X-Type Spring Machine Revolutionizes Speed and Training for Turkish Manufacturer

X-Type spring forming machine Increases Production Speed Fourfold

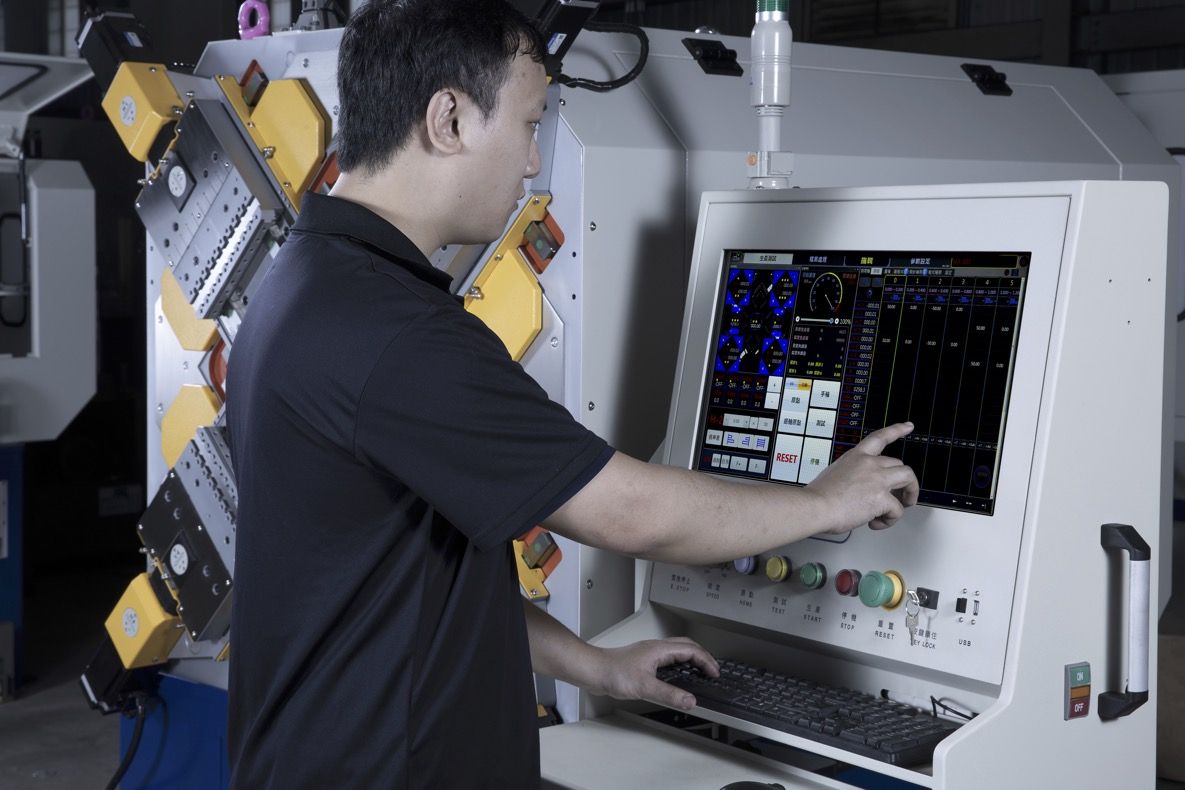

The customer previously used traditional cam spring forming machines to produce springs, which required a lot of time and effort to adjust tool height, left-right and cam position, and feed depth. However, manually adjusting these parameters made it difficult to reproduce the same position as before. Achieving the desired tolerance level was also challenging and depended on the experience level of each technician, resulting in different adjustment frequency, time, and even wire cost. Due to a limited number of skilled technicians and difficulty in training new staff, the overall production speed was slow. Therefore, we recommended the client to use our new X-Type composite spring forming machine, which can easily reproduce the spring production process through the CNC panel and scale settings, eliminating the hassle of technicians' time-consuming adjustments.

Customer Background and Case Introduction

The customer is a medium-sized spring forming machine manufacturer located in Turkey, which previously used traditional cam machines to produce springs. Due to its stable product quality and on-time delivery, the customer established a good reputation in the industry. After several trial orders with a newly developed spring client, the customer received its first big order. However, using traditional cam machines, the customer could only produce 2 springs per minute. Besides, technicians had to spend a lot of time adjusting tools, which affected production capacity and efficiency. To improve this situation, the customer sought our solution.

Why the Customer Chose Us

The customer chose us for two reasons: first, we have rich experience in spring forming machine manufacturing and can provide solutions that meet their needs. Second, our X-Type composite spring forming machine can effectively solve the client's problems with production speed and difficulty in training technicians, thereby improving production capacity and efficiency.

Customer Feedback

After using the X-Type spring forming machine, the custoemr's production speed increased from 2 springs per minute to 8 springs per minute, and efficiency greatly improved. Moreover, due to the CNC panel and scale settings, reproducing springs became easier, reducing the difficulty in training technicians. The customer was very satisfied with the solution we provided and expressed their willingness to continue working with Xinda.

- Related Products

11-axis X-Type spring forming machine

CNC10X, CNC25X, CNC42X, CNC60X

Xinda's X-Type Spring Former stands as a revolutionary innovation in the realm of spring manufacturing, empowering businesses to achieve unparalleled efficiency...

Details