About Us

We Have Accumulated Years of spring forming machine Design Experience and a Wealth of Industrial Expertise.

Xinda is a professional spring forming machine manufacturer. At the beginning of the establishment, we have been devoted ourselves in the manufacturing of universal spring forming machines. We are a group of professionals with expertise in mechanical assembly, processing, motors, software design, and spring manufacturing. The average industry experience of the core members is more than 30 years.

Xinda Milestone

| Year | Milestone |

|---|---|

| 1996 | Established in Wugu Industry Park, Taiwan, covering an area of 330 square meters. |

| 1997 | The first shipment of universal cam spring forming machine. |

| 2000 | Moved the factory to Luzhou District, New Taipei City, Taiwan, covering an area of 1,322 square meters. |

| 2003-2006 | Developed and launched a series of rotating wire cam-type spring forming machines. |

| 2005 | Built the factory in Shulin District, New Taipei City, Taiwan, covering an area of 2,149 square meters. |

| 2011 | Established a subsidiary, Wing Hong Mechanical Co., Ltd. |

| 2011-2015 | Developed a series of camless multi-axis spring forming machines. |

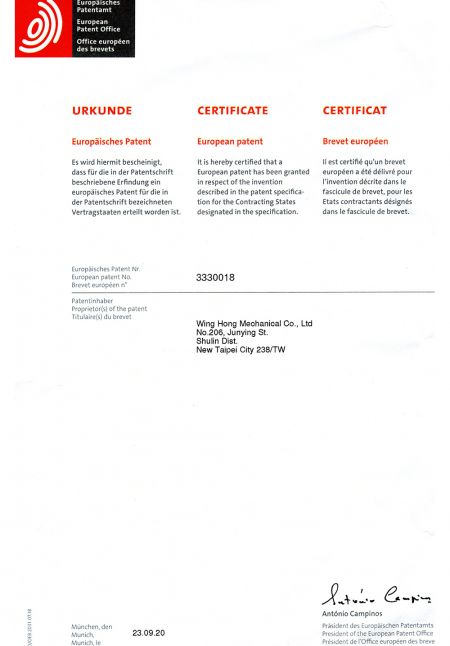

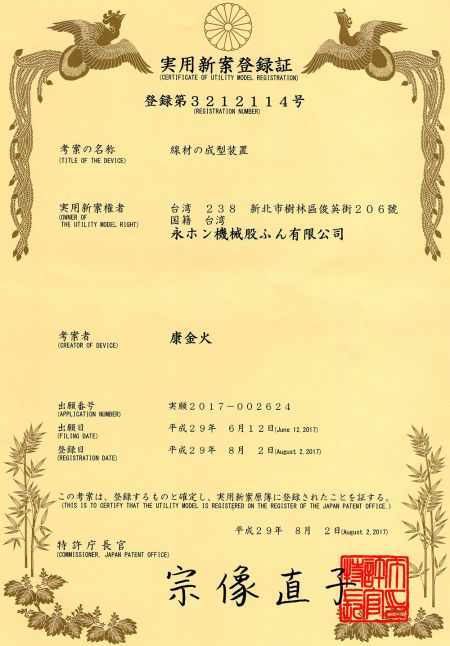

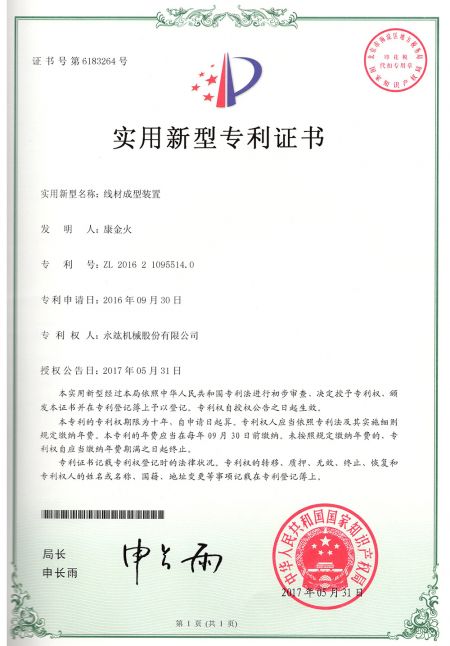

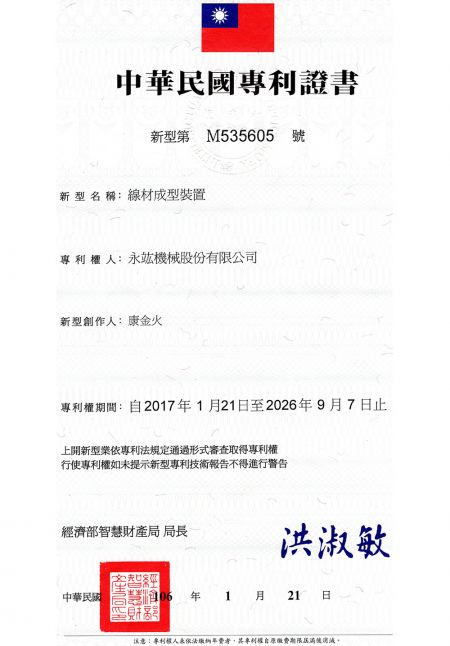

| 2017 | Developed X-Type spring forming machines and obtained multinational patents. |

| 2018 | Developed X-Type spring forming machine with thick wire diameter. |

| 2019 | Developed X-Type spring forming machine with thin wire diameter. |

| Developed the bending mechanism and obtained the associated patent. | |

| Joined EtherCAT Technology Group. | |

| 2020 | Expanded the factory building with a total area of 10,000 square meters. |

| 2021 | Reached a new-generation spring forming machine cooperation project with Siemens Ltd. Digital Industries. |

| 2023 | Introduced the Yamazaki Mazak five-axis machining center. |

Xinda's early product was a two-axis cam-type spring forming machine. To meet diverse customer needs, we have gradually added quill-rotating, wire-rotating spring forming machines and the optional devices such as hook station, servo spinner, etc., and expanded to a variety of spring forming machines with different wire diameters. Later, we launched universal multi-axis spring forming machines without cams, which facilitate the operator to complete spring manufacturing more conveniently and quickly.

In recent years, customization and small batch production have become the latest trend. To meet customers' growing needs, we have invested in R&D and launched the latest X-Typespring forming machine. The X-Type spring forming machine breaks the traditional frame and design concepts of spring forming machines. We have adopted a simple operation panel structure and exclusively developed intuitive operating software, providing a new user experience. The excellent precision and agile production efficiency brought by the X-Type spring forming machine allow customers to realize small batch production.

To improve the quality and technical level of our spring forming machines, we have introduced Yamazaki Mazak's high-precision five-axis machining center for processing the parts of spring forming machines. This five-axis machining center can process surfaces or planes at any position in 3D space, keeping the tool perpendicular or at a specific angle to the work piece surface. It ensures accurate processing even if the work piece contour changes. Additionally, the simultaneous five-axis processing can complete complex operations in one step, avoiding the tolerance generated from disassembly and assembly during turning and milling processes.

We are proud to announce that Xinda is the only manufacturer in Asia and one of the few worldwide to use Yamazaki Mazak's five-axis machining center to process spring forming machine parts. This high-precision five-axis machining center not only improves the quality of our spring forming machines but also assists customers in improving the quality of their spring processing, achieving a win-win situation for the company and customers.

From economical to high-end precision spring forming machines, Xinda is committed to design and quality excellence, adhering to the original intention of innovation for sustainable development. We would like to become a long-term and reliable partner for customers. If you have any spring forming machine needs or questions, please feel free to contact us, and we will be happy to assist you.

Xinda's Video

This video showcases the new generation of spring forming machines created by XINDA together with SIEMENS. The new spring forming machine can achieve several functions such as equipment's energy visualization, servo motor's energy regeneration and energy-saving applications.

0:00 Xinda works closely with Siemens in the development of a new generation of spring forming machines.

0:46 The new generation of spring forming machines can achieve: 1.5 times higher production yield; visualization of energy consumption; servo motor's energy regeneration and energy-saving applications.

1:15 The software and harware soluitons for the new generation of spring forming machines.

2:08 The core technology of the new generation of spring forming machines.

3:41 Through the featured edge computing technology, predictive maintenance, the optimization of after-service can be achieved for a single spring forming machine or the entire production line.

4:20 The successful development of the new generation of spring forming machines is due to teamwork and synergy among all technology partners of Xinda.

4:40 Under the prevailing trends of small batch and multi-variety, customization, and smart manufacturing, Xinda chose to cooperate with Siemens to create even better spring forming machines so as to help customers embrace new business opportunities in the digital era.

Company Photo

- Large spring forming machine Assembly Area

- Small spring forming machine Assembly Area

- Processing Machinery Area

- Tuning Area

- Machining center for processing spring forming machine parts

- Patent Certificate

- Patent certificate for wire forming mechanism of spring forming machine (Europe)

- Patent certificate for wire forming mechanism of spring forming machine (Japan)

- Patent certificate for wire forming mechanism of spring forming machine (China)

- Patent certificate for wire forming mechanism of spring forming machine (Taiwan)

- Patent certificate for bending mechanism of spring forming machine (Taiwan)