11-axis X-Type spring forming machine

CNC10X, CNC25X, CNC42X, CNC60X

spring manufacturing machine, spring former, CNC spring forming machine, CNC spring former, CNC spring forming machine

Xinda's X-Type Spring Former stands as a revolutionary innovation in the realm of spring manufacturing, empowering businesses to achieve unparalleled efficiency and precision. Designed to address the diverse spring production needs of our valued customers, this exceptional machine seamlessly integrates cutting-edge technology with an intelligent operating system, propelling your spring manufacturing capabilities to new heights.

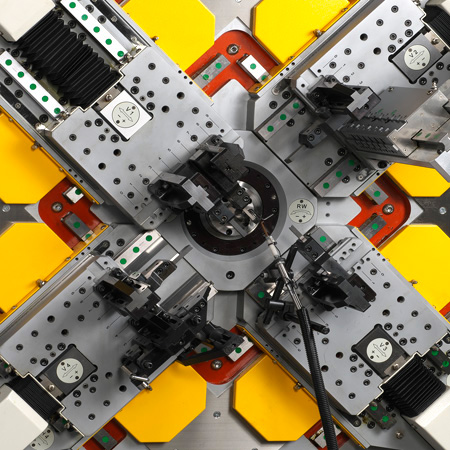

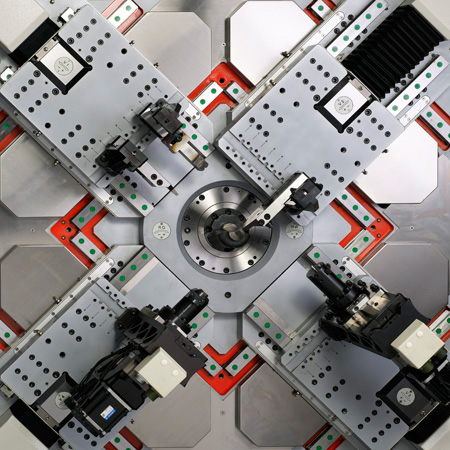

Minimalist Slide Design, Breaking Traditional Constraints

The X-Type Spring Former breaks free from conventional limitations, featuring a minimalist slider design that empowers four processing surfaces to execute both horizontal and vertical movements. This groundbreaking approach transforms the manufacturing process from a traditional 2D realm into a versatile 3D dimension. The enhanced freedom of movement significantly expands the scope of spring forming, enabling unparalleled flexibility and efficiency.

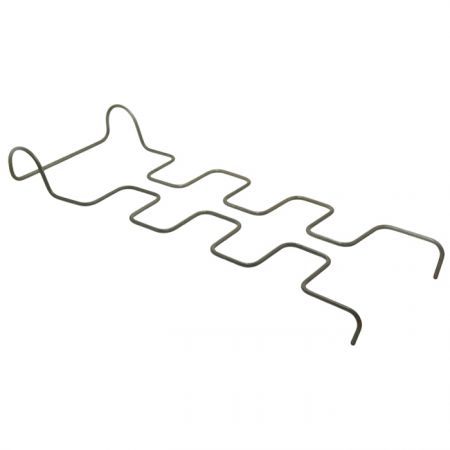

Traditional cam-type or camless spring formers often face challenges when processing complex, multifaceted springs like the one depicted in Figure 1. These machines demand intricate adjustments and manual fine-tuning. In contrast, the X-Type Spring Former can cleverly utilize its flexible slide design to avoid or maneuver to another processing angle, such as using the bending tool in reverse to complete the process (as illustrated in Figure 2), easily achieving the manufacture of complex springs.

Video

The X-Type Spring Former utilizes the flexibility of its slides to effortlessly manufacture complex springs.

Unlocking High-Efficiency Production with Powerful Features

Beyond its groundbreaking slider design, the X-Type Spring Former boasts an array of powerful features that elevate your spring production experience:

• 11-Axis Expandable Design: Equipped with four sets of horizontal and vertical slides, a feed axis, a quill-rotating axis, and a wire-rotating axis, the machine's 11-axis configuration can be expanded to 21 axes, catering to your most intricate spring forming requirements.

• Eliminate Adjustment Troubles: The X-Type Spring Former enables multi-directional stroke control and simulated arm trajectory, eliminating the need for manual fine-tuning after traditional processing, significantly improving production efficiency and accuracy.

• Versatile Spring Manufacturing: The spring machine seamlessly manufactures a wide range of high-difficulty, high-precision springs, including compression springs, single/double torsion springs, battery springs, and various wire forming-related spring products.

Simplifying Operations with an Intelligent Control System

The X-Type Spring Former is equipped with an intelligent control system, simplifying the operation process and allowing you to easily manage spring production:

• Advanced Computer System and User-Friendly Software: Featuring a cutting-edge computer system, an intuitive graphical user interface (GUI), and program optimization functionalities, the machine minimizes unnecessary operations, ensures smooth program execution, and expedites spring forming time.

• A Wealth of Practical Features:

o Timeline Mode: Substantially reduces forming time compared to traditional programming methods.

o Exclusive Overlap Mode: Seamlessly integrates the production processes for each spring, boosting overall productivity.

o Test/Production Consistency: Whether in testing or automatic production mode, the machine maintains consistent speed and angle, enabling operators to effortlessly control precision and quality.

o Self-Diagnosis: Upon startup, the machine automatically diagnoses drive, motor, and hardware status.

o Simplified Program Editing: Simply enter axis values to complete program editing. Tables can be effortlessly converted into timeline mode for intuitive understanding.

o Program Restoration and Undo Functionality: Conveniently edit programs with restore and undo capabilities.

o File Management System: For recurring spring production, programs can be reused without the need for reprogramming.

o USB Port: Import/export programs and automatically upgrade system software via USB or wireless/wired networks.

o CCD Image Support: Capture and store spring sample images.

o Full Touchscreen Operation: Set parameters without a keyboard or mouse.

o Compatible with Swiss or German proximity laser probes.

Optional Accessories to Address Specific Needs

The X-Type Spring Former offers a range of optional accessories to cater to your unique production requirements:

• Servo Spinner/Dual Servo Spinner

• Servo Rotary Gripper

• Servo Cutter

• Laser Probe

• Vision Sensor

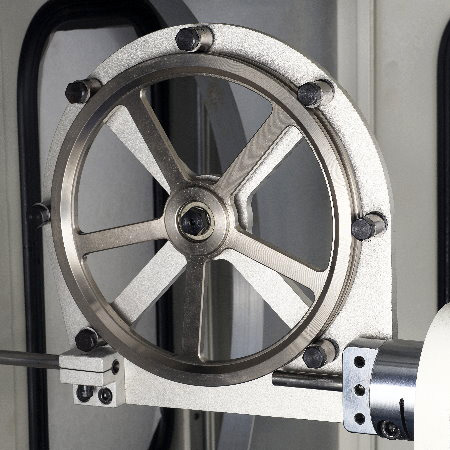

• Hand Wheel (MPG)

• CE Safety Cover

• Wire Set

Basic Specification

| Model Number | CNC10X | CNC25X | CNC42X | CNC60X | |

|---|---|---|---|---|---|

| Forming Capability | Wire Diameter Range (mm) | 0.1-1.0 | 0.6-2.6 | 1.8-4.2 | 3.0-6.0 |

| Max. Outer Diameter (mm) | 16 | 40 | 70 | 90 | |

| Max. Leg Length (mm) | 30 | 60 | 150 | 200 | |

Machine Dimension | Full Length (mm) | 1000 | 1600 | 2320 | 2660 |

| Full Width (mm) | 1520 | 1900 | 2460 | 2800 | |

| Full Height (mm) | 1885 | 1800 | 2080 | 2200 | |

| Weight (kg) | 950 | 1630 | 3500 | - | |

| Power Requirements | Power Supply (V/Hz) | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz |

| Power (kW) | 6.15 | 16.1 | 30.2 | 63.2 | |

| Rated Current (A) | 28 | 42.5 | 80 | 166 | |

| Servo Axes | Standard | 11 | 11 | 11 | 11 |

| Maximum | 18 | 18 | 18 | 18 | |

| Air Pressure Interface | 12 Ports | ||||

| External Storage | USB | ||||

| Ambient Temperature | 0-45°C | ||||

Servo Specification

| Model Number | CNC10X | CNC25X | CNC42X | CNC60X | |

|---|---|---|---|---|---|

| H Axis | Min. Increment (mm) | 0.001 | 0.01 | 0.01 | 0.01 |

| Max. Movement Amount | ± 30 | ± 50 | ± 75 | ± 100 | |

| Max. Speed (m/min.) | 30 | 30 | 24 | 30 | |

| V Axis | Min. Increment (mm) | 0.001 | 0.01 | 0.01 | 0.01 |

| Max. Movement Amount | 75 | 135 | 200 | 260 | |

| Max. Speed (m/min.) | 30 | 30 | 24 | 30 | |

| Wire Feed | Min. Increment (mm) | 0.01 | 0.01 | 0.01 | 0.01 |

| Max. Speed (m/min.) | 120 | 90 | 80 | 90 | |

| Quill Rotating | Min. Increment | 0.1° | 0.1° | 0.1° | 0.1° |

| Max. Speed (rpm) | 500 | 500 | 200 | 200 | |

| Wire Rotating | Min. Increment | 0.1° | 0.1° | 0.1° | 0.1° |

| Max. Speed (rpm) | 150 | 165 | 100 | 80 | |

* Note: All specifications and features are subject to change without notice.

- Download

X-Type Spring Machine Series Specifications

This document provides the specifications for Xinda's X-Type spring machine series, allowing you to quickly understand the features, performance, and differences...

DownloadXinda Spring Machine Specifications Overview

This document compiles the detailed specifications of the entire Xinda spring machine series, helping you quickly understand the features, performance,...

DownloadSpring Machine Catalog: Professional Solutions for Boosting Spring Production Efficiency

Our Spring Machine Catalog offers comprehensive solutions to help you enhance spring production efficiency, improve quality, and reduce costs.

Download- Related Case Study

X-Type Spring Machine Revolutionizes Speed and Training for Turkish Manufacturer

The customer previously used traditional cam spring forming machines to produce springs, which required a lot of time and effort to adjust tool height,...

Read more- Video

The X-Type Spring Former utilizes the flexibility of its slides to effortlessly manufacture complex springs.

The X-Typespring forming machine with servo rotary gripper produces semi-circular tension springs at a production rate of 15.3 pcs./min. This is due to the high accuracy of the machine, the flexibility of the 4-panel design and the coordination of the Timeline software.

The X-Type spring forming machine produces torsion springs with a wire diameter of 0.45mm at a production rate of 9.4 pcs./min. The unique four-panel design can reduce the number of wire rotations, make the wire body more stable, and improve the forming quality.

The X-Type spring forming machine produces double torsion springs with a wire diameter of 1.4mm at an output rate of 6.6 pcs./min. The unique software and hardware design enables the stroke of the spring tool to be flexibly changed according to the shape of the spring.

- Machine Details

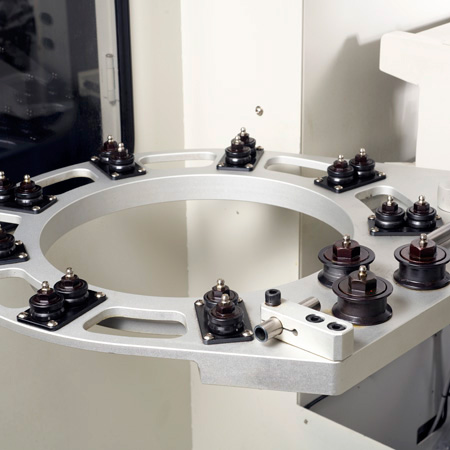

- Working panel of the X-Type spring forming machine.

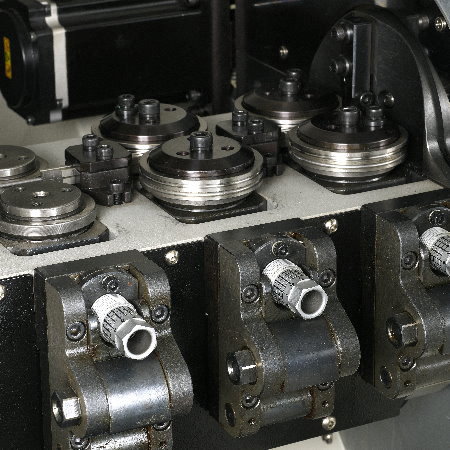

- Straightening set of the X-Type spring forming machine.

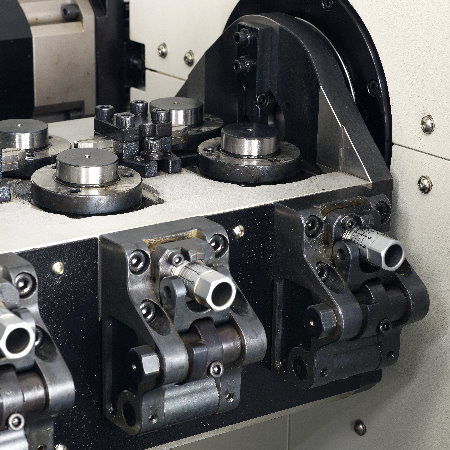

- Feed set of the X-Type spring forming machine.

- Wire reel of the X-Type spring forming machine.

- Servo spinner of the X-Type spring forming machine.

- Dual servo spinner of the X-Type spring forming machine.

- The X-Type spring forming machine with safety cover closed.

- Working panel of the X-Type spring forming machine.

- Feed set of the X-Type spring forming machine.

- Working panel of the X-Type spring forming machine.

- Wire reel of the X-Type spring forming machine.

- Feed set of the X-Type spring forming machine.

- The X-Type spring forming machine with safety cover.

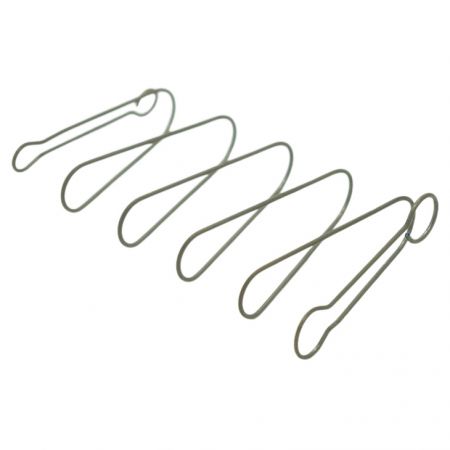

- Spring Examples

- Battery spring processing with X-Type Spring Former.

- Pin torsion spring production planning proposal and spring forming machine with supplementary equipment.

- Tension spring production planning proposal and spring forming machine with supplementary equipment

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Thin wire tension spring production planning proposal and spring forming machine.

- Brake spring production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine.

- Related Products

11-axis Intelligent Energy-saving Spring Machine

CNC42XE

The X-Type Intelligent Energy-Saving Spring Machine is a next-generation spring machine developed...

DetailsX-Flex 6-Axis Spring Forming Machine

CNC25F

The X-Flex spring forming machine, designed by Xinda, is crafted for spring manufacturers seeking...

Details

11-axis X-Type spring forming machine | Comprehensive Solutions in Camless Spring Forming Machines for Industrial Buyers

Xinda Machine Co., Ltd., established in 1996 in Taiwan, leads in manufacturing spring and wire forming machinery. With a focus on innovation and quality, our product lineup includes 11-axis X-Type spring forming machine, cam spring forming machinery, camless spring forming machines, patented X-type spring forming machines, specialized spring machines, wire forming machines. Xinda specializes in bespoke engineering, offering customized spring and wire forming machines tailored to meet unique industrial requirements. Our comprehensive approach covers design, development, and after-sales support, delivering precision-engineered solutions that enhance production capabilities.

Dedicated to revolutionizing spring manufacturing, Xinda has been at the forefront of providing advanced spring and wire forming machines since 1996. With an unwavering commitment to innovation and quality, we offer a comprehensive range of machines, including full-servo spring formers, universal multi-axis, camless and specialized spring forming solutions. Our state-of-the-art technology ensures unmatched precision, efficiency and reliability to meet the diverse needs of industries worldwide. Experience the future of spring manufacturing with Xinda's expertly engineered solutions - where excellence meets precision.

Xinda has been offering spring and wire forming machines since 1996, both with advanced spring forming technology and 40 years of experience, Xinda ensures each customer's demands are met.