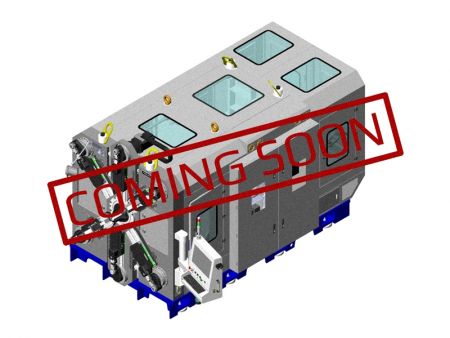

11-axis Camless spring forming machine - Wire-rotating Type

CNC1320W, CNC1350W, CNC1380W

spring former without cams, spring manufacturing machine, CNC spring forming machine, CNC spring former, CNC spring forming machine

The cam-free spring forming machine is a highly efficient full-servo spring forming machine designed for mass-produced spring manufacturing. With eight independently operated servo slides, a feed axis, a quill-rotating axis, and a wire-rotating axis, this machine has a total of 11 axes. The full-servo system eliminates the need for time-consuming cam arrangement, thus reducing processing time and cost.

Core Technology

- Equipped with the German Beckhoff control system, easily implementing complex algorithms to achieve the best production efficiency.

- Equipped with EtherCAT master protocol chip to gain high-speed and stable control of each axis.

- With Microsoft Windows operating system, the first step to exercise Industry 4.0 and the Internet of Things.

- With unique Timeline Mode, the time for spring forming can be shortened by 100~300%, compared to the traditional programming way.

- Exclusive Overlap Mode perfectly connects the procedures between each spring production cycle to increases the production speed.

- No matter testing or automatic production process, the machine's production speed and angle are the same, allowing the operator to better manage the accuracy and quality.

- Self-detection at startup for the status of driver, motor, software & hardware.

- Fill in the values of each axis to simply complete the program editing. The table can be converted into a Timeline Mode at will, and the rich display allows users to see at a glance.

- Software program has undo and redo functions for easy editing.

- With file management system, the program can be reused and no rewriting required when producing the same spring.

- USB port can import/export programs.

- Control system software can be automatically upgraded through the USB port or the wireless/wired network (manually available).

- Support CCD image to save springs photos.

- Use full touch screen, no more need keyboard and mouse for setting.

- Can be used with Swiss or German proximity laser sensors.

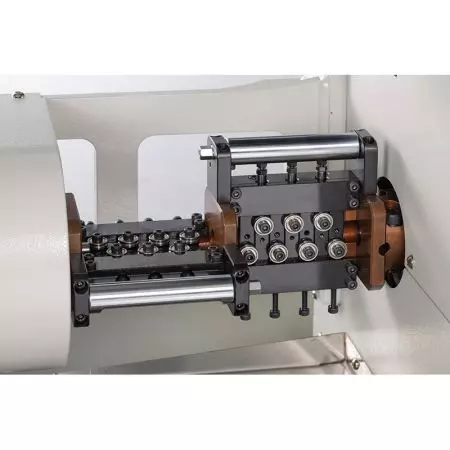

Machine Features

- Surface finish of the gear transmission system is grinding processed and the accuracy reaches DIN5 level.

- Wire-rotating system to realize forming and cutting at any angle.

- The feed roller and the straightening set are equipped with a quick disassembly mechanism, which is convenient for adjusting the wire direction.

- Wire-rotating mechanism adopts a belt-type design which is easy to maintain and repair.

- Lightweight feed set to reduce inertia and improve response speed.

- Graphical user interface for easier to get started.

- Sensor compensation function to stabilize production quality.

- Remote troubleshooting and online update service.

For CNC1320W:

- Equipped with a swing cylinder to control the initial tension of the spring body.

- Equipped with maintenance-free reducer and gearbox.

For CNC1350W:

- Equipped with automatic slide lubrication system.

Optional Equipment

- Servo Spinner

- Dual Servo Spinner

- Servo Hook Station

- Servo Rotary Gripper

- Servo Cutter

- Laser Sensor

- Vision Sensor

- Hand Wheel (MPG)

- CE Safety Cover

- Wire Set

Basic Specification

| Model Number | CNC1320W | CNC1350W | CNC1380W | |

|---|---|---|---|---|

| Forming Capability | Wire Diameter Range (mm) | 0.2-2.3 | 2.6-5.0 | 3.0-8.0 |

| Max. Outer Diameter (mm) | 40 | 120 | 160 | |

| Max. Leg Length (mm) | 60 | 100 | 180 | |

| Machine Dimension | Full Length (mm) | 1600 | 2850 | 4350 |

| Full Width (mm) | 1750 | 2110 | 3070 | |

| Full Height (mm) | 1850 | 2100 | 2430 | |

| Weight (kg) | 1530 | 4720 | - | |

| Power Requirements | Power Supply (V/Hz) | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz | 220-440V/3P 50/60Hz |

| Power (kW) | 17.7 | 59.2 | 100.2 | |

| Rated Current (A) | 50 | 155 | 265 | |

| Servo Axes | Standard | 11 | 11 | 11 |

| Maximum | 21 | 21 | 21 | |

| Air Pressure Interface | 12ports | |||

| External Storage | USB | |||

| Ambient Temperature | 0-45°C | |||

Servo Specification

| Model Number | CNC1320W | CNC1350W | CNC1380W | |

|---|---|---|---|---|

| Servo Slide | Min. Increment | 1 | 1 | 1 |

| Max. Movement Amount | 8000 | 8000 | 8000 | |

| Max. Speed (rpm) | 250 | 165 | 60 | |

| Wire Feed | Min. Increment (mm) | 0.01 | 0.01 | 0.01 |

| Max. Speed (m/min.) | 90 | 90 | 90 | |

| Quill Rotating | Min. Increment | 0.1° | 0.1° | 0.1° |

| Max. Speed (rpm) | 500 | 200 | 133 | |

| Wire Rotating | Min. Increment | 0.1° | 0.1° | 0.1° |

| Max. Speed (rpm) | 165 | 80 | 60 | |

* Note: All specifications and features are subject to change without notice.

- Download

Camless Spring Machine Series Specifications

This document provides the specifications for Xinda's camless spring machine series, allowing you to quickly understand the features, performance, and differences...

DownloadXinda Spring Machine Specifications Overview

This document compiles the detailed specifications of the entire Xinda spring machine series, helping you quickly understand the features, performance,...

DownloadSpring Machine Catalog: Professional Solutions for Boosting Spring Production Efficiency

Our Spring Machine Catalog offers comprehensive solutions to help you enhance spring production efficiency, improve quality, and reduce costs.

Download- Related Case Study

Camless spring machine Boosts Production by 2 times for an Indian Factory

Xinda successfully helped a spring factory in central India solve production efficiency problems by providing the camless spring forming machine that meets...

Read more- Video

11-axis camless wire-rotating spring forming machine produces external double torsion springs at a production rate of 23.5 pcs./min

11-axis cam-free wire-rotating spring forming machine produces stainless steel clips at a production rate of 13.2 pcs./min

11-axis camless wire-rotating spring forming machine produces hose clip at a production rate of 101.7 pcs./min

- Machine Details

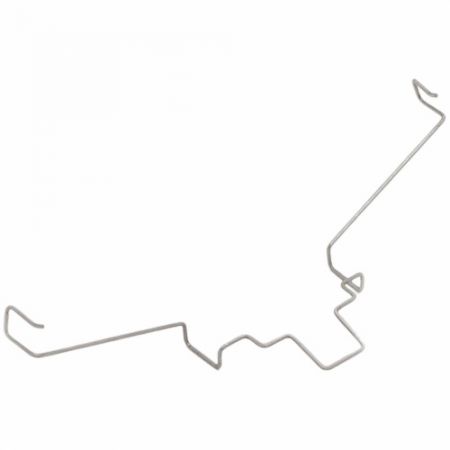

- Spring Examples

- Torsion spring production planning proposal and spring forming machine with supplementary equipment.

- Torsion spring production planning proposal and spring forming machine.

- Wire form production planning proposal and spring forming machine with supplementary equipment.

- Hose clip production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Formed wire spring production planning proposal and spring forming machine.

- Formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Fishing tackle spring production planning proposal and spring forming machine with supplementary equipment.

- Single torsion spring production planning proposal and spring forming machine with supplementary equipment.

- Double torsion spring production planning proposal and spring forming machine with supplementary equipment.

- Stepped formed wire spring production planning proposal and spring forming machine with supplementary equipment.

- Related Products

10-axis Camless spring forming machine - Basic Type

CNC1020

This advanced camless spring forming machine features a highly efficient full-servo system,...

Details

11-axis Camless spring forming machine - Wire-rotating Type | Comprehensive Solutions in Camless Spring Forming Machines for Industrial Buyers

Xinda Machine Co., Ltd., established in 1996 in Taiwan, leads in manufacturing spring and wire forming machinery. With a focus on innovation and quality, our product lineup includes 11-axis Camless spring forming machine - Wire-rotating Type, cam spring forming machinery, camless spring forming machines, patented X-type spring forming machines, specialized spring machines, wire forming machines. Xinda specializes in bespoke engineering, offering customized spring and wire forming machines tailored to meet unique industrial requirements. Our comprehensive approach covers design, development, and after-sales support, delivering precision-engineered solutions that enhance production capabilities.

Dedicated to revolutionizing spring manufacturing, Xinda has been at the forefront of providing advanced spring and wire forming machines since 1996. With an unwavering commitment to innovation and quality, we offer a comprehensive range of machines, including full-servo spring formers, universal multi-axis, camless and specialized spring forming solutions. Our state-of-the-art technology ensures unmatched precision, efficiency and reliability to meet the diverse needs of industries worldwide. Experience the future of spring manufacturing with Xinda's expertly engineered solutions - where excellence meets precision.

Xinda has been offering spring and wire forming machines since 1996, both with advanced spring forming technology and 40 years of experience, Xinda ensures each customer's demands are met.