The spring forming machine with Overlap Mode seamlessly connects the processes between each spring production cycle, perfectly increasing the production speed.

What are the benefits of the spring forming machine's Overlap Mode?

What is the Overlap Mode of the spring forming machine?

Xinda's spring forming machine provides a unique Overlap Mode. The Overlap Mode helps the operator seamlessly connect the processing procedures between the springs and increase the production speed. It is a feature of Xinda's timeline software.

The working principle of the Overlap Mode is to make a time overlap between the currently produced spring and the next-to-be-produced spring in the producing process. That is to say, when the current spring has not been finished, the next spring can be processed.

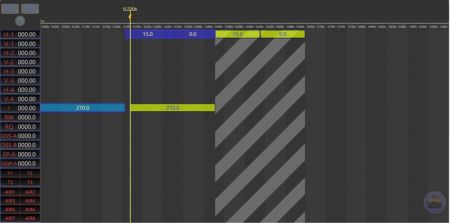

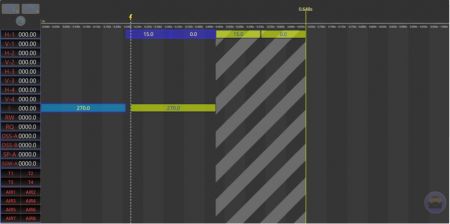

The Overlap Mode is further demonstrated with the following four illustrations.

Figure A shows the first spring’s wire-feeding and cutting process. The processing time is 0.428 seconds.

Figure B shows that, with the Overlap Mode, the second spring’s wire-feeding action can be executed in 0.22 seconds.

Therefore, the actual production process of the spring falls in the time segment of 0.428 seconds ~ 0.648 seconds (the gray slashed part). That is, after using the Overlap Mode, the total production time is reduced from 0.428 seconds to 0.22 seconds. The production capacity is increased by 94.5%.

*Note: The above production speed is for reference only. The actual production rate will depend on the adjustment condition of the spring forming machine and the complexity of the spring.

To meet customers' demands for faster, more precise and more complex spring production, Xinda's Programming Studio will keep pace with the times and continuously develop advanced functions. The new version of the software can be obtained by online download, and is provided to customers for free update. Xinda's Programming Studio is equipped on the camless and X-Type machines series.

Xinda has accumulated rich experience in designing and manufacturing spring forming machines since the earliest two-axis cam spring forming machine era. We are happy to provide customers with a full range of spring forming machine solutions to help you solve any problems related to the production of springs.

- Related Case Study

X-Type Spring Machine Revolutionizes Speed and Training for Turkish Manufacturer

The customer previously used traditional cam spring forming machines to produce springs, which required a lot of time and effort to adjust tool height,...

Read more- Related Products

11-axis Camless spring forming machine - Wire-rotating Type

CNC1320W, CNC1350W, CNC1380W

The cam-free spring forming machine is a highly efficient full-servo spring forming machine...

Details11-axis X-Type spring forming machine

CNC10X, CNC25X, CNC42X, CNC60X

Xinda's X-Type Spring Former stands as a revolutionary innovation in the realm of spring manufacturing,...

Details